Ghatkopar, Mumbai, Maharashtra

- GST NO. : 27AAECJ7356H1ZA

BLISTER Packing Machines

Jicon is a reputable Blister Packing Machine Manufacturer. We have a reputation for quality and are experts in creating innovative packaging solutions for a range of sectors. Our cutting-edge blister packaging machines are designed with accuracy, dependability, and efficiency in mind.

Whether you manufacture consumer items, food, or medicines, our equipment guarantees flawless blister packaging that improves the protection and shelf appeal of your products. Jicon is unique in terms of quality, innovation, and client happiness.

Invest in Jicon as your manufacturer of blister packing machines to improve your packaging procedures. For industry-leading equipment that redefines packaging standards, get in touch with us right now.

| Business Type | Manufacturer, Exporter, Supplier |

| Automatic Grade | Automatic |

| Application | Industrial |

| Model No. | Blistrip-I XT |

| Max. Web Width | 148mm |

| Max. Forming depth | 10mm (Expandable up to 20mm) |

| Max. Output (Packs/Min) | 150 (2 UP), 300 (3 UP) |

| Max. Strokes/Min | 150 |

BLISTRIP-I xt is a single track automatic blister packing machine for packing of tablets, capsules, dragees etc. in blister packs using PVC-Alu packaging materials. The blister forming, product feeding and sealing operations are continuous by rotary motion while the indexing and punching operations are of intermittent reciprocating motion. The output capacity of the machine depends on the product characteristics.

In case of slightly curved or flat tablets up to 10 mm dia an output of 150 packs per minute can be optimally achieved.

Features :

- Special tool design reduces trim waste

- All change over parts and adjustments accessible from front side

- Easy and quick change over reduces material wastage and down time

- Simpler operation reduces operator fatigue-increases output

- Very compact in size

- Combi packs possible for better utilization of capacity and packaging materials

- Edge-to-Edge cutting eliminates trim waste between packs

- Compact footprint

| Business Type | Manufacturer, Exporter, Supplier |

| Application | Industrial |

| Model No. | Blistrip-II |

| Max. Web Width | 210mm |

| Max. Forming depth | 10mm (Expandable up to 20mm) |

| Max. Output (Packs/Min) | 300 (2 UP), 450 (3 UP) |

| Max. Strokes/Min | 150 |

With Jicon as your go-to High-Speed Automatic Blister Packing Machine Manufacturer, you can embrace the future of pharmaceutical packaging. We are a recognised company that sets the standard for innovation and provides the pharmaceutical industry with cutting-edge goods.

At Jicon, we understand the value of precision and productivity in the manufacturing of medicines. The speed, precision, and dependability requirements of the industry are met by our high-speed automatic blister packing machines. Our devices guarantee the flawless packaging of pharmaceutical items through cutting-edge technology and precise engineering, increasing output and decreasing downtime.

Jicon is unique because of our dedication to excellence. With great care and attention to detail, every High-Speed Automatic Blister Packing Machine is made by GMP requirements and international standards. Because of the versatility of our machines, a wide range of pharmaceutical items may be packaged securely and they can accommodate different blister shapes.

We are pleased to be partners in your success as well as producers. Jicon's committed maintenance and support services guarantee the efficient operation of your manufacturing lines. It maximises productivity while reducing interruptions.

Selecting Jicon as your Blister Packing Machine Manufacturer in India is an investment in dependability, productivity, and the advancement of pharmaceutical packaging. Join the ranks of business titans who entrust Jicon with their cutting-edge packaging requirements.

Jicon is the partner you've been looking for if you need creative ideas and precision engineering. Get in touch with us right now to find out how our automatic blister packing machines with high speeds can improve your pharmaceutical production operations and establish new standards for efficiency, accuracy, and speed.

Jicon is a shining example of quality in pharmaceutical packaging equipment. Our industry-redefining High-Speed Automatic Blister Packing Machines guarantee flawless, precise packing. You can rely on Jicon for cutting-edge technology, constant support, and commitment to international quality standards. Boost your pharmaceutical production with Jicon, the place where dependability and innovation collide.

| Business Type | Manufacturer, Exporter, Supplier |

| Base Material - Max Width (Cold Form Laminated ALU Foil/PVC/PVC-PVDC) 0.2 to 0.3 Thick; In Reel Form Max. 250. | 140mm |

| Lidding Mat. Max. Width(HSL Coated Hard Alu/Glassine Foil)0.02 to 0.04 Thick, In Reel Form Max220 | 140mm |

| Min. Pack Size | 40mm x 45mm |

| Max. Forming Depth | 10 (EXTENDABLE TO 20) |

| Max. Output* (Packs/Min) | 30 (1UP), 60 (2 UP) |

| Max. Pack Size | 110mm x 130mm (1 UP), 110mm x 62mm (2 UP) |

| Max. Strokes/Min | 30 |

ALBLIS is a versatile ‘Flat Plate’ intermittent motion automatic blister packing machine that can produce Alu-Alu blister packs by cold forming method as well as PVC-Alu blister packs by thermoforming method. This machine is utilized for packing of smaller and regular shaped solid articles such as pharmaceutical Tablets, Capsules, Dragees etc. in Alu-Alu or PVC-Alu. blister packs. This Machine can also be used for packing of Ampoules, Vials, Tubes in PVC-Alu blister packs. The blister forming, sealing, indexing and punching operations are of intermittent reciprocating motion. Various types and styles of product feeding devices are offered to suit different application.

Features :

- Simple Operation

- Quick Change Over

- Suitable for Alu-Alu, PVC-Alu and PVC-Paper Blister Packs

- R&D and Formulation Development applications

- Can pack Tablets, Capsules, Dragees and also vials, Ampules, Tubes, Creams

- Can be supplied without automatic product feeding system

| Business Type | Manufacturer, Supplier |

| Automatic Grade | Automatic |

| Application | Industrial |

| Dimensions | 4400mm X 1200mm X 2100mm (H) |

| Base Material - Max Width (Cold Form Laminated ALU Foil/PVC/PVC-PVDC)0.2 to 0.3 Thick; In Reel Form Max.(250) | 260mm |

| Lidding Mat. Max Width (HSL Coated Hard ALU/Glassine Foil)0.02 to 0.04 Thick, In Reel Form Max 220 | 260mm |

| Max. Pack Size | 250mm x 140mm |

| Max. Forming Depth | 14mm |

| Max. Output* (Packs/Min) | 70 (Alu-Alu) (2 Track), 200 (Alu-PVC) (4 Track) |

| Max. Strokes/Min | 35 (Alu - Alu), 50 (Alu - PVC) |

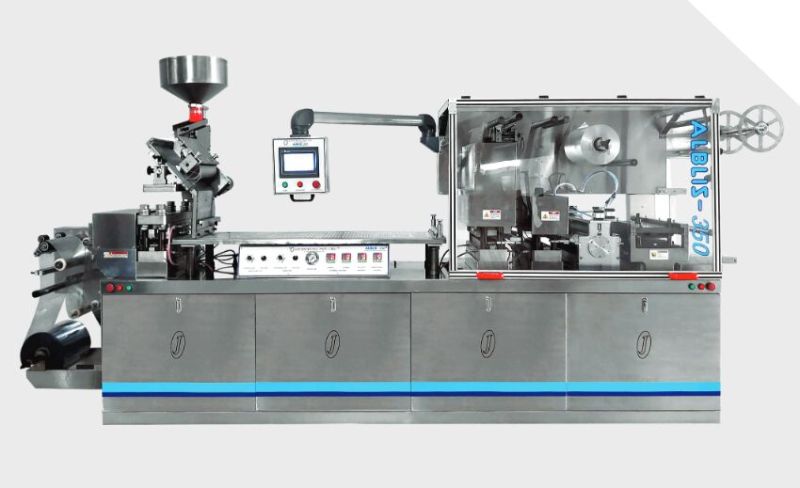

| Model NO. | ALBLIS-II |

ALBLIS is a versatile ‘Flat Plate’ intermittent motion automatic blister packing machine that can produce Alu-Alu blister packs by cold forming method as well as PVC-Alu blister packs by thermoforming method. This machine is utilized for packing of smaller and regular shaped solid articles such as pharmaceutical Tablets, Capsules, Dragees etc. in Alu-Alu or PVC-Alu blister packs. This Machine can also be used for packing of Ampoules, Vials, Tubes in PVC-Alu blister packs. The blister forming, sealing, indexing and punching operations are of intermittent reciprocating motion. Various types and styles of product feeding devices are offered to suit different application.

The standard configuration of machine is for producing of Alu-Alu blisters suitable for pharmaceutical tablets, Capsules, Dragees etc. The standard configuration may be opted out or can be combined with other configurations.

Features

- Quick Change Over

- Simple Operation

- Suitable for Alu-Alu, PVC-Alu and PVC-Paper Blister Packs

- Versatile Machine can pack Tablets, Capsules, Dragees and also vials, Ampules, Tubes, Creams

- Cost Efficient

- Easy Maintainence

| Business Type | Manufacturer, Exporter, Supplier |

| Automatic Grade | Automatic |

| Application | Industrial |

| Dimensions | 4400mm X 1200mm X 2100mm (H) |

| Base Material - Max Width (Cold Form Laminated ALU Foil/PVC/PVC-PVDC)0.2 to 0.3 Thick; In Reel Form Max.(250) | 350mm |

| Lidding Mat Max. Width (HSL Coated Hard ALU/Glassine Foil)0.02 to 0.04 Thick, In Reel Form Max.(220) | 350mm |

| Min. Forming Area | 340mm x 160mm |

| Max. Forming Depth | 14mm |

| Max. Output* (Packs/Min) | Up to 400 packs per minute depending on pack size and pack configuration |

| Max. Strokes/Min | 35 (Alu - Alu), 50 (Alu - PVC) |

ALBLIS-350 is a versatile ‘Flat Plate’ intermittent motion automatic blister packing machine that can produce Alu-Alu blister packs by cold forming method as well as PVC-Alu blister packs by thermoforming method. This is a ‘Flat-Forming-Flat-Sealing’ type machine that is utilized for packing of smaller and regular shaped solid articles such as pharmaceutical tablets, capsules, dragees etc., in Alu-Alu or PVC-Alu blister packs. This machine can also be used for packing of Ampoules, Vials, Tubes as well as cream. paste, jam etc in PVC-Alu blister packs. The blister forming, sealing, batch code embossing, pack perforation, indexing and punching operations are of intermittent reciprocating motion. Various types and styles of product feeding devices are offered to suit different application.

The output capacity of the machine depends on the product characteristics and thus on the type of feeding device. Normally for cold forming operation to produce Alu-Alu blisters this machine would operate at 25-35 cycles per minute and for thermoforming operation to produce PVC-Alu blisters it would operate at 30-50 cycles per minute.

Features :

- Simple Operation

- Large Format Area for Maximising your output

- Heavy construction of machine ensures consistent performance of the machine for a long life

- Simple to Operate, Simple to Maintain ensures minimum downtime of machine

- Affordable Change Parts

- Space efficient machine - maximum output per square foot of your clean room

- Machine can be specced with different types of feeding systems for different requirements

- Can handle a wide range of packing materials with capability of thermoforming as well as cold forming

- Hii gh output-up-to 400* packs per minute

- Sturdy Construction

- Wide format area